ABOUT US

ABOUT US

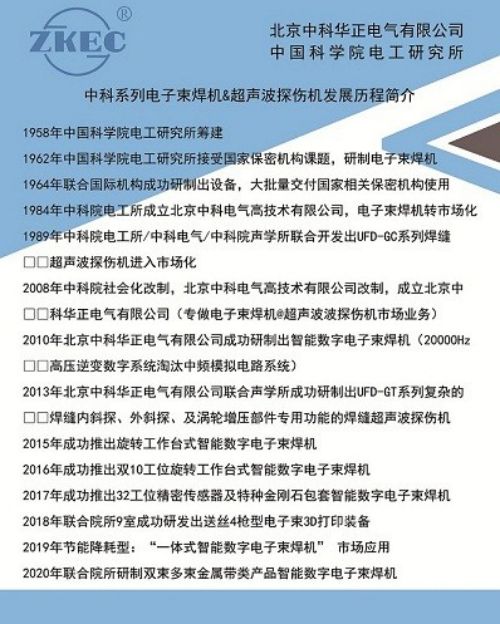

In March 2008, in response to the call of the Chinese Academy of Sciences for socialized restructuring, Beijing Zhongke Huazheng Electric Co., Ltd. was restructured into Beijing Zhongke Huazheng Electric Co., Ltd. from the Special Processing Equipment Department of Beijing Zhongke Electric High Technology Co., Ltd; It is affiliated to the holding subsidiary of Institute of Electrical Engineering of Chinese Academy of Sciences, among which there are about 450 current employees of Institute of Electrical Engineering of Chinese Academy of Sciences, 31 senior employees of China Science and Technology Corporation, and 10 employees with medium and senior professional titles

Beijing Zhongke Huazheng Electric Co., Ltd. is mainly engaged in the research, development and equipment manufacturing of electron beam welding technology, vacuum application technology and ultrasonic flaw detection technology; At the same time, it also acts as an agent for international high-end CNC processing equipment and accessories.

Beijing Zhongke Electric High Technology Co., Ltd., founded in 1984 with a registered capital of 18 million yuan, is mainly engaged in the R&D and manufacturing of electromechanical equipment, environmental protection equipment, medical equipment and new energy products, and can operate the import and export business of its own products and technologies. The Special Processing Equipment Department of Beijing Zhongke Electric High Technology Co., Ltd. is mainly engaged in the research, development and equipment manufacturing of electron beam welding technology, vacuum application technology and ultrasonic flaw detection technology.

As early as 1962, the electron beam department was established and developed by the "electron beam welding research group" of the Institute of Electrical Engineering of the Chinese Academy of Sciences. It is also one of the first institutions engaged in electron beam welding research in China, with strong technical strength. Since the mid-1980s, several years of research and improvement have been carried out on the electron beam welding equipment on the production line to meet the requirements of continuous two shift operation and stable and reliable performance. Finally, it has been successfully developed in China and has been recognized by the Ministry of Science and Technology and users.

Since the implementation of "one institute and two systems" by the Chinese Academy of Sciences in 1986, the electron beam welding equipment has provided more than 400 sets of multi series and multi specification electron beam welding equipment for China's automobile industry, national defense industry, metallurgy industry, engineering machinery, atomic energy and other industries, and has been exported to dozens of overseas markets. It has solved the key technical problems in production for many customers and created huge economic and social benefits. The vast majority of electron beam welding equipment is directly used in the production line. 95% of the automobile and motorcycle industries at home and abroad use electron beam welding. Typical cases are as follows:

Electron Beam Welding of Turbine Assembly of Hydraulic Torque Converter on Shanghai General BUICK Car Electron beam forming welding of the cockpit module beam of Shanghai Volkswagen POLO and TORAN commercial vehicles Welding of Hangzhou IVECO Automobile Gear Line Welding of SAIC Chery Automobile Gear Line Welding of Great Wall Motors gear line FAW Automobile Gear Line Welding Dongfeng Automobile gear line welding --- etc Electron beam sealing of radioisotope titanium tubes for cancer treatment Local vacuum electron beam welding of satellite attitude adjustment shell Electron beam welding of planetary gear frame and differential gear frame Electron beam welding of synchronizer gears in automobile transmission Electron beam penetration welding of silicone oil shock absorber Electron beam sealing welding of automobile air conditioner piston (24 stations) Bimetal double gun electron beam sliding seal continuous welding production line Electron beam welding for high-precision sensors Electron beam welding of automobile power battery Electronic target (aluminum and titanium) |

High vacuum universal electron beam welding machine The EBW-G series gear electron beam welding machine developed by our company was rated as a national new product in 1989 and a fist product in Beijing New Technology Test Zone in 1990. He has won the gold medal and various science and technology awards of the International Expo for many times. The company has an external processing workshop, five electron beam welders of various types, and technical experts with decades of welding experience as the backing to provide customers with a variety of welding technical guidance and services. EBW-G series gear electron beam welding machine produced by our company, its supporting UFD-GB/GC full-automatic digital intelligent ultrasonic gear weld flaw detector, UFD-GW full-automatic digital intelligent ultrasonic AT automatic transmission gear carrier weld flaw detector, and UFD -/GSC full-automatic digital intelligent ultrasonic planetary gear carrier weld flaw detector. Up to now, nearly 200 sets of such equipment have been provided for customers

The vacuum application technology department of Beijing Zhongke Huazheng Electric Co., Ltd. has a strong technical force, and has decades of rich experience in vacuum equipment design and production. Its products involve production equipment for electric vacuum devices, coating production equipment, ultra-high vacuum research and production equipment, and various ultra-high vacuum standard parts. Be able to design and manufacture according to customer requirements. The products have been widely used in national scientific research and other departments, and have been highly recognized. The company has strong non-standard product design ability, and can design and manufacture non-standard products that satisfy customers according to their requirements. The vacuum application equipment manufactured by our company is widely used in aerospace, electronic information, atomic energy, scientific research, building decoration, mechanical automobile, optics, new energy and other industries. The equipment works stably and reliably, and is highly praised by users.

In 2010, it cooperated with Barton Institute of Ukraine, was the agent of electron beam welding machine in China of Barton Institute of Ukraine, and was the after-sales technical service center of electron beam welding machine in China of Barton Institute of Ukraine.